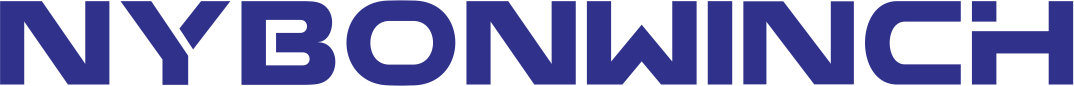

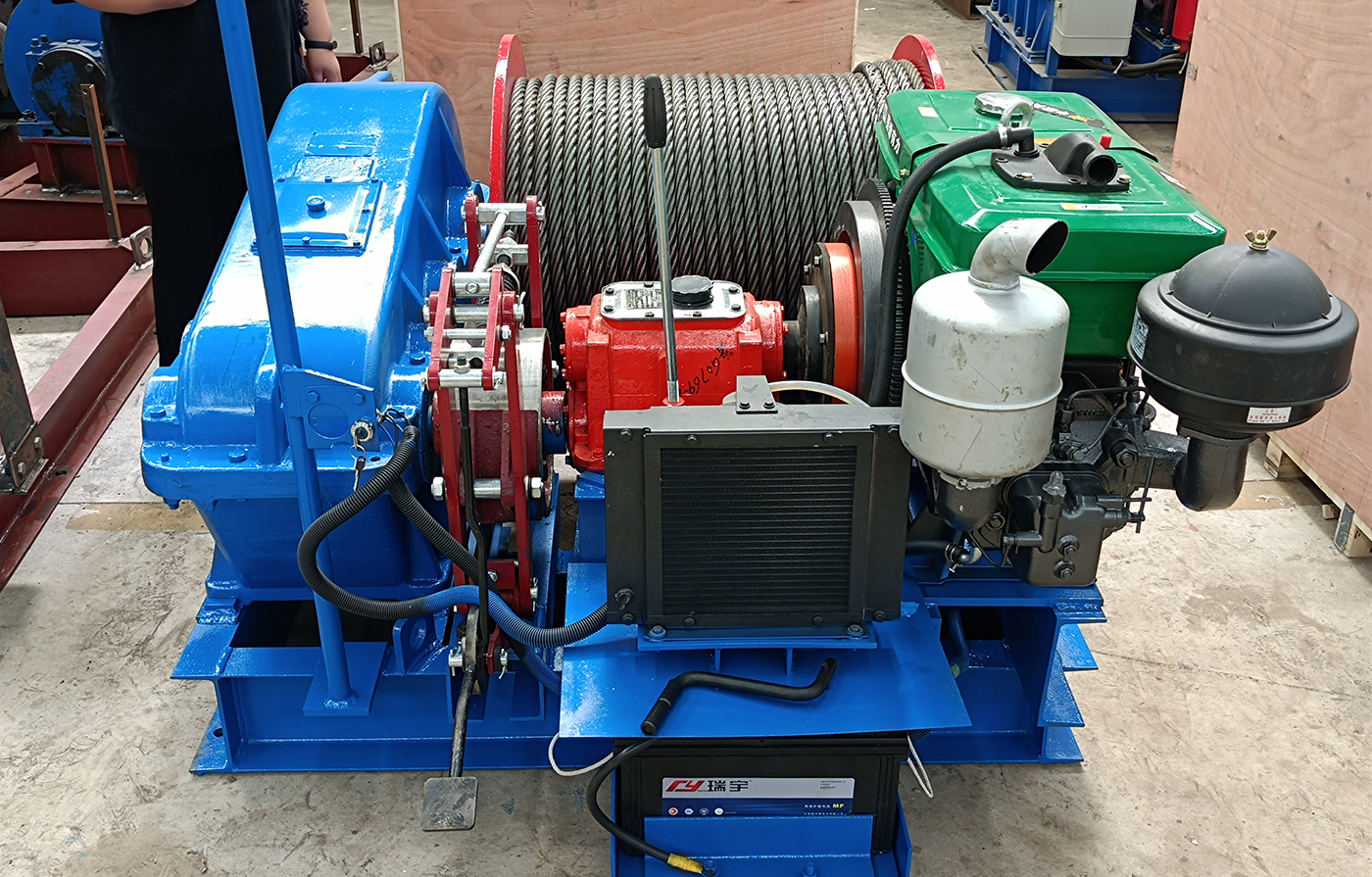

Diesel Winch

Diesel engine power winch is slow speed diesel engine driven gear winch; It is mainly used for hoisting, drag-and-drop, loading cargos, such as all kinds of large concrete construction, steel constructions installation and disassembly; The winches are applied to construction company, mine, factory and other installation engineering projects company;

This series winch is mainly used for large and oversize concrete construction of steel installation and disassembly of mechanical equipment. This structural characteristic is wire rope orderly arrangement lifting is safe and reliable. It is suitable for bridge port and road and bridge engineering and large factories and mines engineering equipments installation.

Diesel Winch Features

- Smallvolume, lightweight, convenience in using and transferring

- Driving stably,Very light noise

- With big drum rope capacity to make you a wide range of choice for the lifting height or pulling length.

- Adjustable lifting or pulling speed for different usage environment.

- High efficiency and labor cost savings

Basic parameters

| Model | Rated Load (KN) | Average Speed of Rope(m/min) | Capacity of Rope(M) | Rope Diameter(MM) | Diesel Power(KW) |

|---|---|---|---|---|---|

| JMC2 | 20 | 16 | 150 | 13 | 7.5 |

| JMC5 | 50 | 10 | 270 | 21.5 | 11 |

| JMC6 | 60 | 9.5 | 270 | 24 | 15 |

| JMC8 | 80 | 8 | 250 | 26 | 15 |

| JMC10 | 100 | 8 | 170 | 30 | 22 |

| JMC25 | 250 | 9 | 700 | 48 | 55 |

| JMC65 | 650 | 10.5 | 3600 | 64 | 160 |

The Scope And Characteristics Of Diesel Engine Winch :

- 1. Widely used in trasmission line construction in the bar,tower,tight line operation,or tools and lifting heavy.

- 2. The hoist weight,especially suitable for field without power site use.

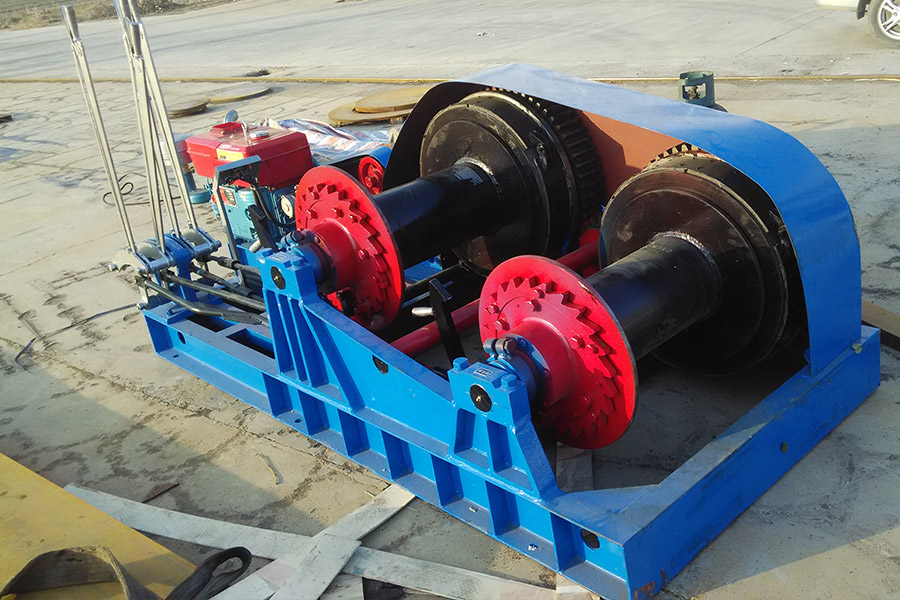

Hand control diesel winch

- Double drum diesel engine power series winch, slow speed electric control winch can be equipped with worm reducer for occasions with high safety requirements.

- In addition to manual operation, the control system of the sliding winch also has a hydraulic control system, which greatly reduces the labor intensity of the operator and improves the work efficiency.

- The fast and slow speed diesel winch can be matched with all kinds of special equipment such as overhead cranes, port cranes, shipyards, cement machinery and truck cranes. traction.

12 ton Hand control fast speed diesel winch

Diesel Engine

Double Drum Diesel Winch

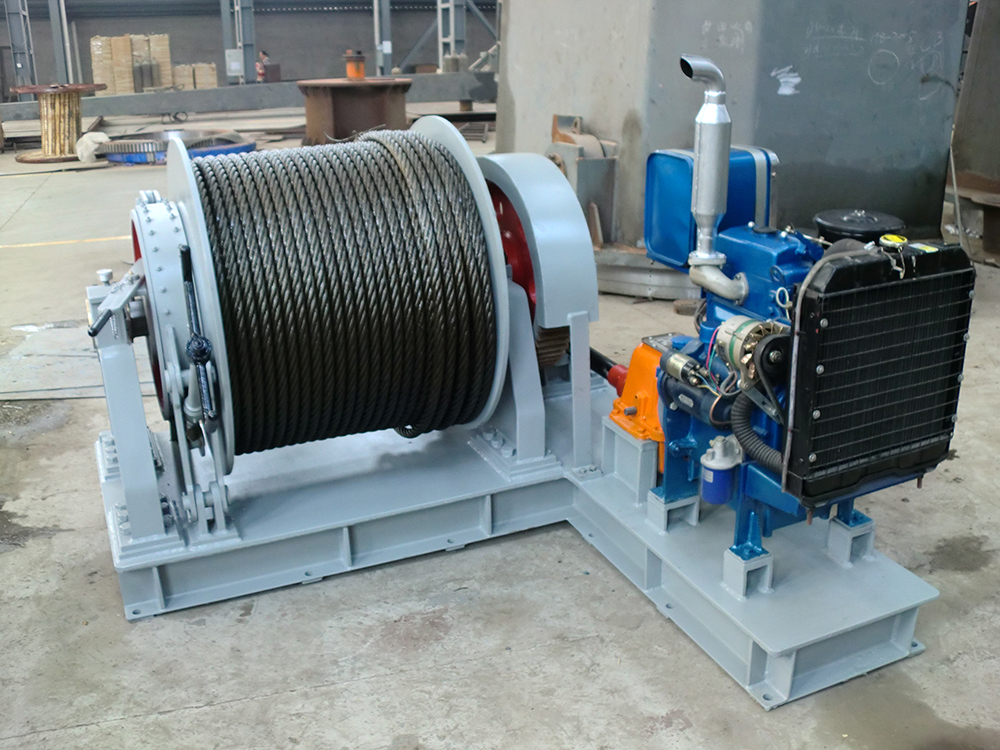

Marine Diesel Winch

- Diesel windlasses are usually installed on the main deck of the ship’s fore and stern for the ship to lift anchors and drop anchors. Windlasses are usually used in conjunction with winches. Its development trend is to use one unit to realize operations such as anchor lifting, mooring, automatic mooring and cable tie.

- The diesel windlass is mainly composed of base, bracket, chain wheel, brake, chain wheel, gearbox, electric control system (except manual windlass), etc.

4t-300m Diesel Engine Mooring Winch

4 ton Diesel Mooring Winch

20 ton Diesel Mooring Winch

15 ton Diesel Mooring Winch

please tell us when you Choose Marine diesel Winch

1. What’s the information should I provide when inquiry about the diesel engine powered winch?

- Capacity.

- Rope drum capacity/ how many ropes do you need (Unit: m)?

- Tell us your target winch model;(If you have)

- The Speed requirement(Unit: m/min)

- Note: It will be better if you have winch working sketch;

2. What are inspection standard for load test of diesel engine powered winch?

- Dynamic load test : 1.1 times rated load.

- Static load test: 1.25 times rated load.

3. How about maintenance of diesel engine powered winch?

- Lubricating: Working performance and service life of all mechanisms of crane depend on lubricating to a big extent.

- Steel wire rope: Fracture of wire has to be specially noticed. A new steel wire rope has to be changed immediately with the condition of broken wire, broken strands and wear loss to scrapping standard.

- Pulley block: Mainly check rope race wearing condition, check whether wheel flange is cracked and whether pulley could get stuck in the axle or not

- Brake: Check one time per shift; The brake should be in accurate movement, and pins do not allow to be stuck. Brake shoes shall fit brake wheels correctly; the brake shoes interval shall be equal to open them.